Selective absorbing glass

POSITION >>

HOME

>

Selective absorbing glass

>

Green glass |

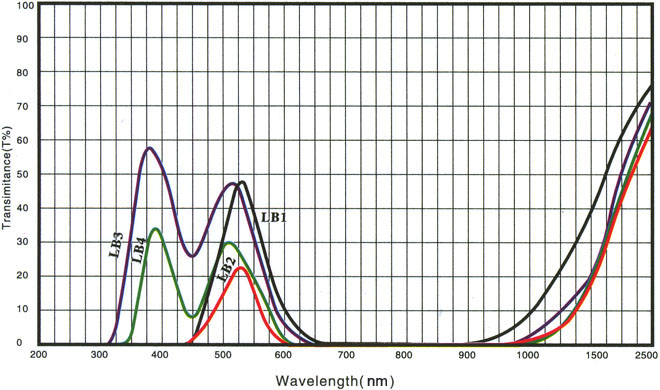

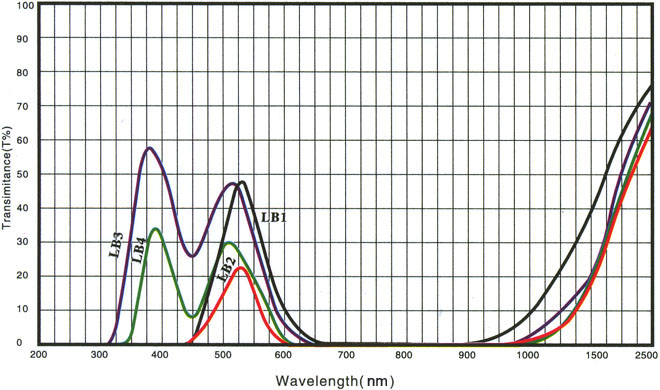

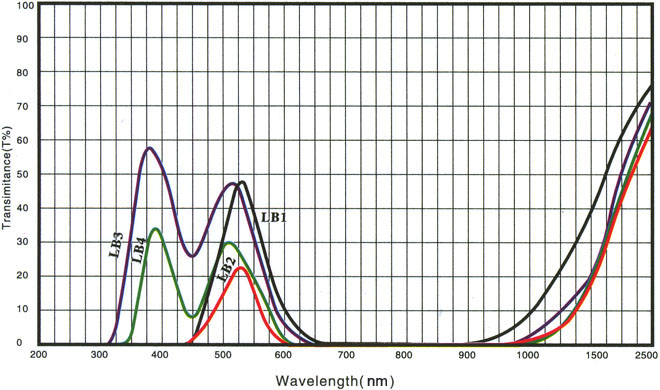

Model | Thickness | A[2856k] | D65 | Chemical Stability | ND | α×10-7 | Tg | Ts | S | (mm) | x | y | Y | x | y | Y | DA | DW | (/℃) | (℃) | (℃) | LB1 | 2 | 0.328 | 0.593 | 24.6 | 0.268 | 0.586 | 28.2 | 1 | 3 | 1.524 | 96 | 535 | 599 | 2.52 | LB2 | 2 | 0.25 | 0.669 | 9.7 | 0.216 | 0.658 | 11.9 | 1 | 2 | 1.524 | 96 | 535 | 599 | 2.52 | LB3 | 2 | 0.252 | 0.502 | 23.7 | 0.196 | 0.374 | 29.3 | 1 | 1 | 1.523 | 98 | 526 | 597 | 2.52 | LB4 | 2 | 0.23 | 0.516 | 16.3 | 0.183 | 0.387 | 20.7 | 1 | 1 | 1.523 | 89 | 525 | 598 | 2.52 |

Model | Thickness | 430(nm) | 450(nm) | 520(nm) | 530(nm) | 650(nm) | Bubbles | Stripe | Stress | (mm) | LB1 | 2 | ≤0.4 | | | ≥41.9 | ≤3.2 | C-B | 4 | 3 | LB2 | 2 | | ≤0.2 | | ≥18.3 | ≤0.2 | C-B | 4 | 3 | LB3 | 2 | | 15.2~29.0 | ≥40.0 | | ≤1.7 | C-B | 4 | 3 | LB4 | 2 | | 6.0~15.9 | ≥24.1 | | ≤0.2 | C-B | 4 | 3 |

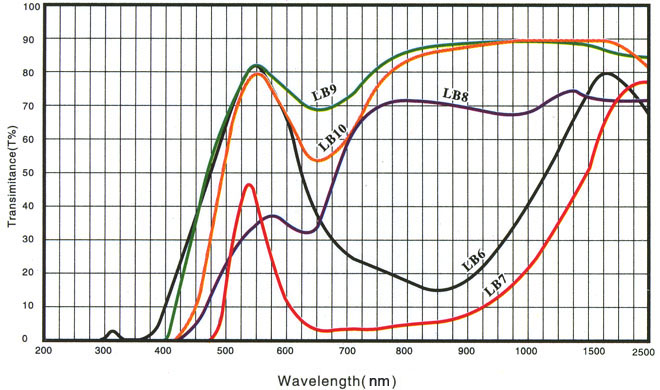

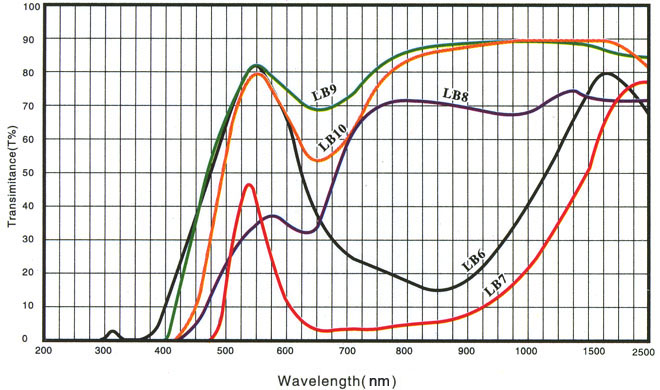

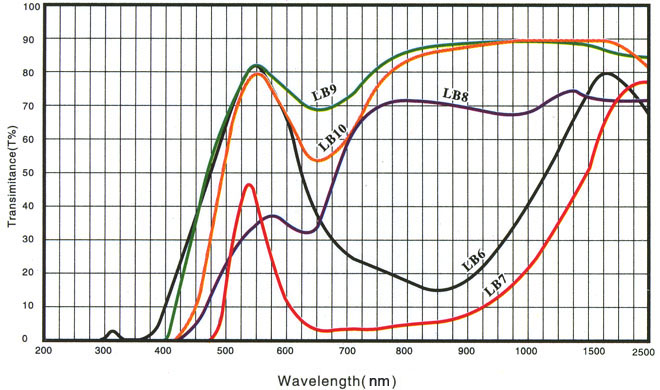

Model | Thickness | A[2856k] | D65 | Chemical Stability | ND | α×10-7 | Tg | Ts | S | (mm) | x | y | Y | x | y | Y | DA | DW | (/℃) | (℃) | (℃) | LB6 | 2 | 0.426 | 0.468 | 71.9 | 0.32 | 0.424 | 73.6 | 6 | 5 | 1.534 | 100 | 421 | 463 | 2.83 | LB7 | 2 | 0.36 | 0.603 | 25.6 | 0.308 | 0.629 | 28.4 | 1 | 2 | 1.547 | 104 | 458 | 526 | 2.85 | LB8 | 2 | 0.496 | 0.459 | 34.9 | 0.42 | 0.475 | 32.3 | 1 | 2 | 1.523 | | | | 2.52 | LB9 | 2 | 0.462 | 0.452 | 86.7 | 0.353 | 0.429 | 85.2 | 1 | 2 | 1.547 | 104 | 458 | 526 | 2.85 | LB10 | 2 | 0.472 | 0.477 | 79.2 | 0.383 | 0.495 | 77.6 | 1 | 3 | 1.547 | 104 | 458 | 526 | 2.85 |

Model | Thickness | 400 (nm) | 420 (nm) | 460 (nm) | 480 (nm) | 550 (nm) | 560 (nm) | 620 (nm) | 650 (nm) | 660 (nm) | Bubbles | Stripe | Stress | (mm) | LB6 | 2 | | | 41.7~50.1 | | | ≥79.4 | | | 25.1~33.1 | C | 3C | 4 | LB7 | 2 | | | | ≤8.0 | 32.0-45.0 @545 | | ≤8.0 | | | C-B | 3C | 3 | LB8 | 2 | | ≤1.3 | | | | 30.3~43.9 | | 25.2-40.0 @640 | | C-B | 3C | 3 | LB9 | 2 | ≤2.0 | | | | ≥82.0 | | | 65.0~70.0 | | C-B | 3C | 3 | LB10 | 2 | | ≤1.0 | | | ≥72.0 | | | 50.0~60.0 | | C-B | 3C | 3 |

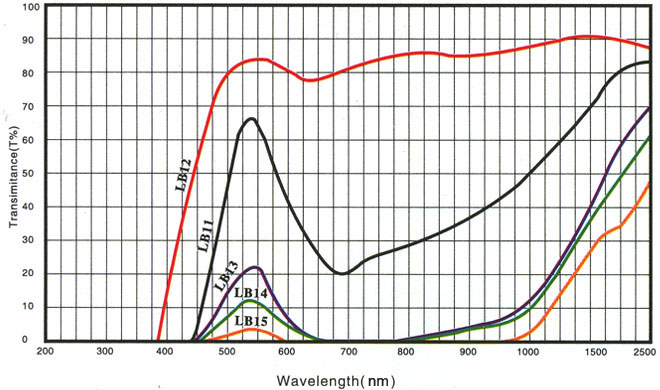

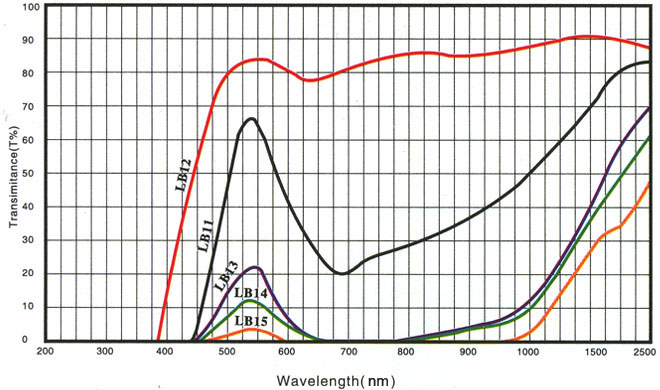

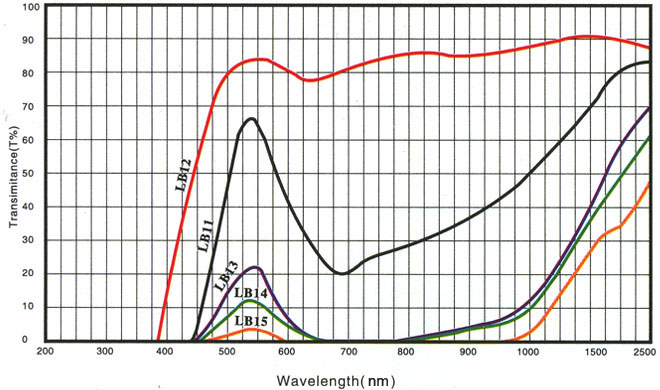

Model | Thickness | A[2856k] | D65 | Chemical Stability | ND | α×10-7 | Tg | Ts | S | (mm) | x | y | Y | x | y | Y | DA | DW | (/℃) | (℃) | (℃) | LB11 | 2 | 0.435 | 0.528 | 53 | 0.364 | 0.56 | 54.4 | 1 | 2 | 1.547 | 104 | 458 | 526 | 2.85 | LB12 | 2 | 0.463 | 0.433 | 87.3 | 0.342 | 0.388 | 84.9 | 3 | 4 | 1.536 | 95 | 534 | 606 | 2.73 | LB13 | 1 | 0.352 | 0.568 | 15.1 | 0.284 | 0.554 | 16.9 | 1 | 3 | 1.527 | 98 | 597 | 663 | 2.53 | LB14 | 1 | 0.369 | 0.576 | 8.9 | 0.307 | 0.588 | 9.8 | 1 | 3 | 1.527 | 98 | 597 | 663 | 2.53 | LB15 | 1 | 0.351 | 0.601 | 2.2 | 0.299 | 0.617 | 2.5 | 1 | 3 | 1.527 | 98 | 597 | 663 | 2.53 |

Model | Thickness | 360 (nm) | 420 (nm) | 480 (nm) | 540 (nm) | 550 (nm) | 620 (nm) | 650 (nm) | 680 (nm) | Bubbles | Stripe | Stress | (mm) | LB11 | 2 | | ≤0.4 | | ≥65.0 | | | | 17.0~24.0 | C-B | 3C | 3 | LB12 | 2 | ≤0.8 | | | | ≥79.4 | | | | C-B | 3C | 3 | LB13 | 1 | | | ≤13.8 | 17.4~30.3 | | ≤12.6 | ≥72.5 | | C-B | 4 | 3 | LB14 | 1 | | | ≤7.6 | 7.6~17.4 | | ≤8.1 | | | C-B | 4 | 3 | LB15 | 1 | | | ≤3.2 | ≥2.0 | | ≤4.2 | | | C-B | 4 | 3 |

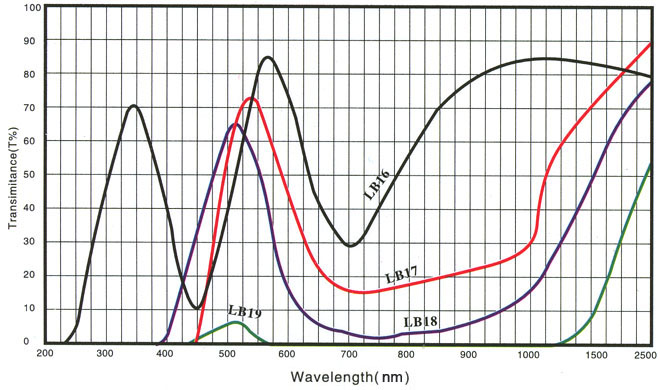

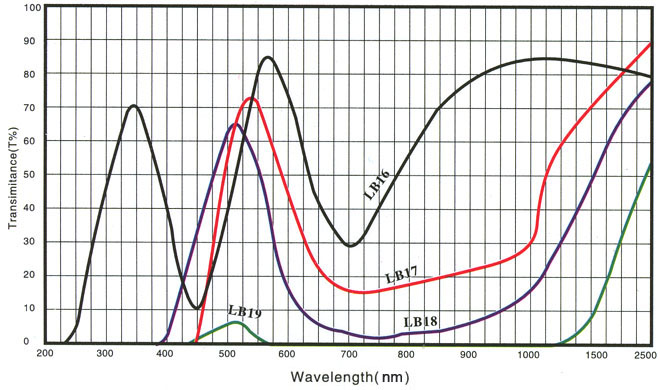

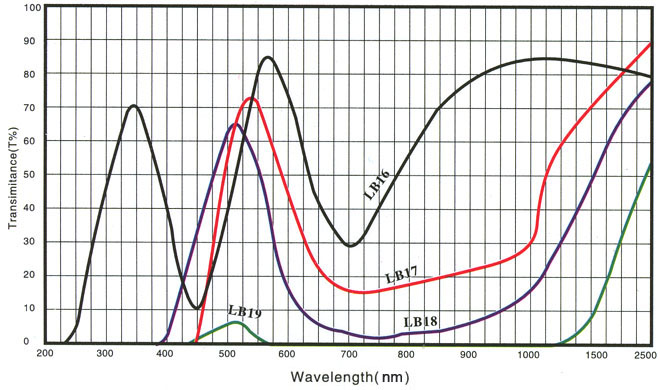

Model | Thickness | A[2856k] | D65 | Chemical Stability | ND | α×10-7 | Tg | Ts | S | (mm) | x | y | Y | x | y | Y | DA | DW | (/℃) | (℃) | (℃) | LB16 | 2 | 0.484 | 0.476 | 74 | 0.405 | 0.483 | 70.2 | 6 | 5 | 1.535 | 100 | 421 | 463 | 2.84 | LB17 | 2 | 0.434 | 0.518 | 56.4 | 0.356 | 0.541 | 58 | 1 | 2 | 1.547 | 104 | 458 | 526 | 2.85 | LB18 | 2 | 0.377 | 0.543 | 40.9 | 0.299 | 0.536 | 44.8 | 1 | 2 | 1.547 | 104 | 458 | 526 | 2.85 | LB19 | 2 | 0.161 | 0.525 | 2.7 | 0.143 | 0.399 | 3.7 | 1 | 3 | 1.544 | 96 | 535 | 599 | 2.52 |

Model | Thickness | 450 (nm) | 460 (nm) | 510 (nm) | 520 (nm) | 530 (nm) | 560 (nm) | 600 (nm) | 660 (nm) | 750 (nm) | Bubbles | Stripe | Stress | (mm) | LB16 | 2 | | 9.0~16.0 | | | | ≥83.6 | | 35.0~42.0 | | D-C | 3C | 4 | LB17 | 2 | ≤1.5 | | | | ≥68.0 | | ≤46.0 | | ≤20.1 | C-B | 3C | 3 | LB18 | 2 | ≤32.8 | | | ≥62.8 | | | ≤18.5 | | ≤2.1 | C-B | 3C | 3 | LB19 | 2 | | ≤3.0 | 6.0~10.0 | | | ≤2.5 | | | | C-B | 4 | 3 |

|